Facing Challenges with Traditional Space Planning Tools?

Discover how a leading CPG brand, in partnership with Shelf IQ®, revolutionized their space planning efforts and achieved remarkable results.

Prior to Shelf IQ, this renowned CPG brand's category teams faced the same challenges in space planning that many businesses encounter: complex and outdated tools in planogram drawing that hindered efficiency and required coding skills.

Enter the Director of Solutions. His mission? Empower the category teams with optimal tools and processes that would bring simplicity and agility, while maintaining control and transparency, back into the space planning process. He recognized the need for a flexible solution that could accommodate diverse retailer and category requirements. In 2020, this leader collaborated with Nuqleous and integrated Shelf IQ, a user-friendly, automated space planning tool.

Next, a seasoned category manager at the company known for her innovative problem-solving skills adopted Shelf IQ for her team. She was responsible for creating 750 store-group planograms, a task that consumed a significant amount of time prior to Shelf IQ, spanning 6-12 weeks. As customer and retailer demands increased, she recognized the need for store-specific planograms. Although this idea seemed challenging, she set out to revolutionize her planogram process. With automation capabilities at her disposal, she harnessed the full power of Shelf IQ and skyrocketed to completing an impressive 4,600 store-specific planograms in just a matter of days! Talk about speed and efficiency!

Clunky, slow, and out of date, our old space planning process was like a patchwork of duct tape and bubble gum. It got the job done, but it added unnecessary complexity to the process.Director of Solutions

Leading CPG Company

Tailored Processes

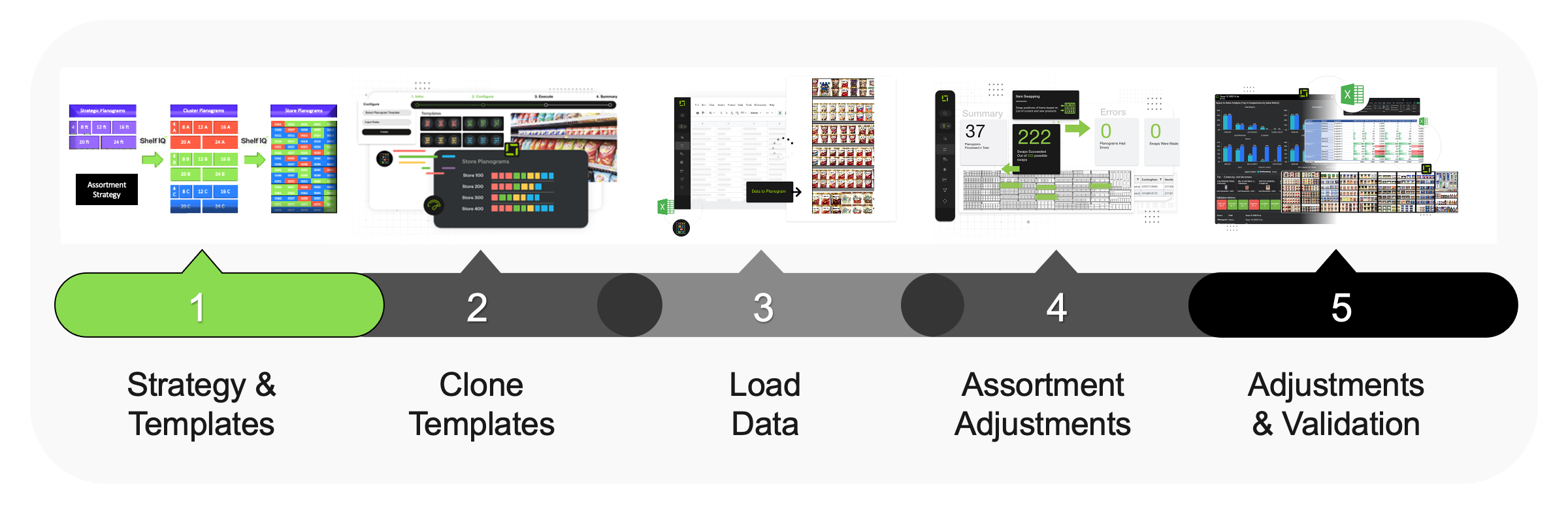

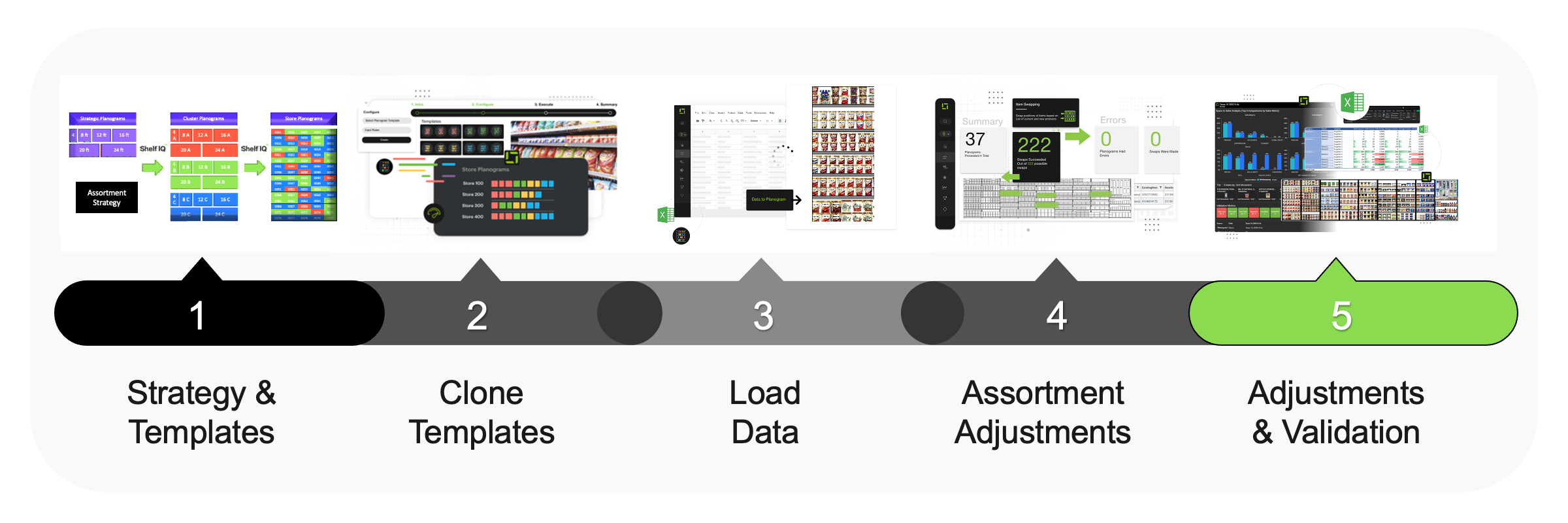

THE CATEGORY MANAGER DEVELOPED A FIVE-STEP PLANOGRAM PROCESS THAT ENHANCED EFFICIENCY AND ACCURACY IN HER SPACE PLANNING.

Shelf IQ became the ultimate sidekick for her category team, offering a user-friendly, no-code solution that put control back in their hands. Drawing strategy with templates, planogram creation through cloning, data loading, assortment adjustments, and planogram validation with Shelf IQ became a breeze, allowing the team to do what they do best: focus on the data-driven, strategic aspects of space planning.

The Solution

PLANOGRAM TEMPLATE DEPLOYMENT & VALIDATION

1. Create templates aligned with the draw strategy to ensure cohesive planograms.

Building templates using the Shelf IQ tool ensures that every action taken is aligned with the overarching draw strategy, enabling a cohesive and layered approach to constructing planograms. This approach focuses on core assortment while maintaining placement consistency, ensures buyer alignment at each step, allows for minor adjustments along the way, thereby reducing surprises at the end of the process.

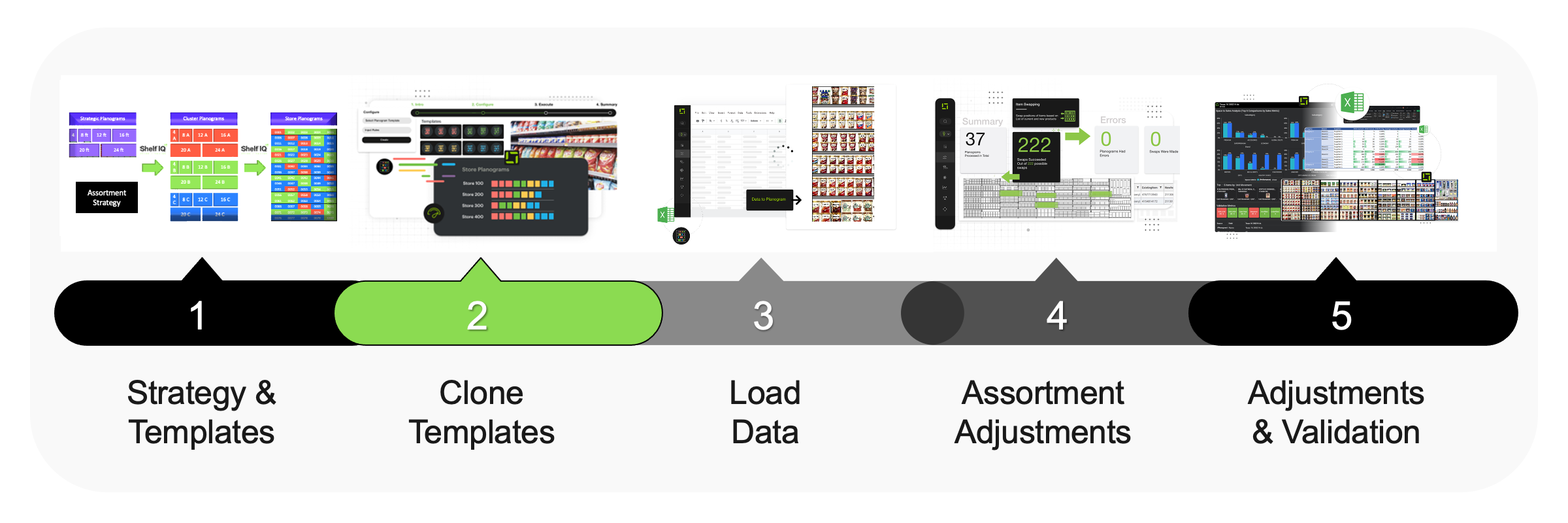

2. Efficient planogram creation using cloning or versioning in Shelf IQ.

Shelf IQ enables efficient planogram creation through cloning, also known as versioning. Running Shelf IQ initiates the automated process, generating numerous planograms within seconds.

To streamline the planogram creation and versioning process, start by listing the desired planograms or versions. Shelf IQ provides a template with extensive planogram fields, simplifying the task. Indicate the templates to be versioned and make any necessary additions or modifications to planogram fields, such as adding an assortment group for regional item placement. Next, copy and paste the data from the Excel spreadsheet into the planogram cloning tool, mapping it to the appropriate template folder.

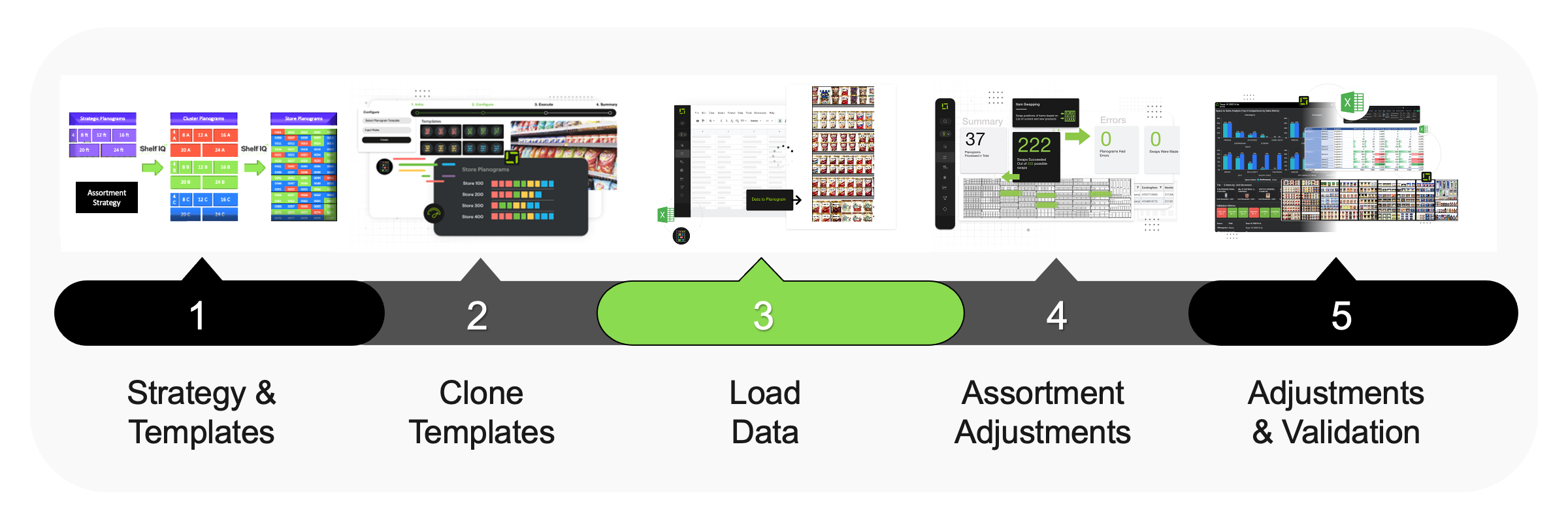

3. Integrate accurate data into the planograms using the Shelf IQ Data Import Wizard.

After creating the planograms, the next step is to integrate the data into the planograms to ensure accurate and up-to-date information. The Shelf IQ Data Import Wizard simplifies this process by providing an easy-to-use interface. You can load product libraries, performance data, or both simultaneously. Whether it's data you created or received from the retailer, the Data Import Wizard allows you to map the data source, verify space planning fields, and automatically handle tasks like creating DSNs or PSPs.

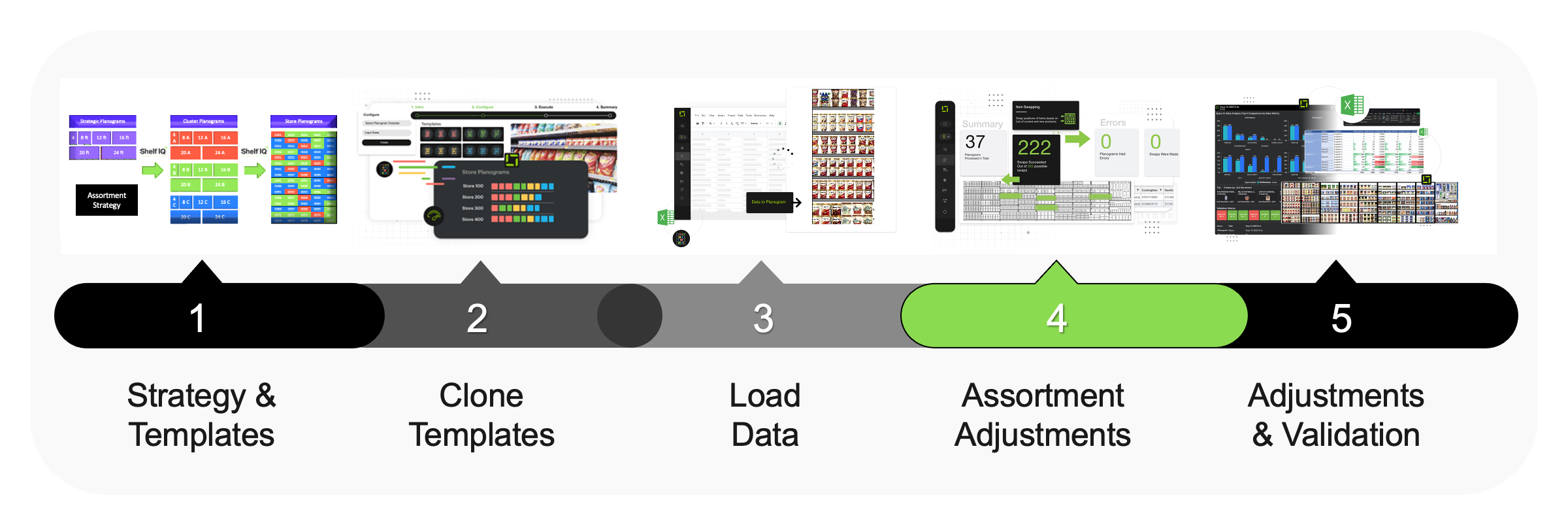

4. Optimize planogram effectiveness with assortment adjustments and actions in Shelf IQ.

With the cloned planograms and loaded data, the next step is to actively manage and optimize the planogram’s effectiveness. Shelf IQ offers a wide range of actions to choose from, including item swapping, item slotting, position deletion, and creating floating shelves for tracking. Assortment adjustments can be made across hundreds of planograms without the need to open individual projects, showcasing the convenience and efficiency of the process.

5. Thoroughly validate planograms with the Shelf IQ validation tool to ensure accuracy and alignment.

Thoroughly validating the planograms after making assortment adjustments is crucial to guarantee their accuracy and alignment with the overall strategy. The Shelf IQ validation tool plays a crucial role in this process by setting parameters and identifying any issues. The validation tool provides specific locations within the planograms where these issues can be addressed, such as low Days of Supply (DOS) or identifying Pack and a Half violations (PnH). This validation feature ensures the accuracy of the changes made without the arduous task of individually reviewing every planogram.

"Through this five-step process, we can confidently achieve our goal in significantly less time, thanks to the efficiency of Shelf IQ."

Category Manager

The Results

STORE-SPECIFIC PLANOGRAMS BECAME THE NEW STANDARD.

With enhanced control and adaptability, the brand's category team was able to optimize efficiency and scalability. Plus, the collaboration and alignment with retailers reached new heights, paving the way for stronger partnerships and mutual success.

This success story with Shelf IQ demonstrates the transformative power of technology in space planning.

By embracing Shelf IQ, they streamlined planogram creation, data integration, and assortment adjustments, transforming their process into an efficient, agile, and data-driven endeavor. If you're ready to achieve the full potential of your space planning efforts, we invite you to check out Shelf IQ. Gain flexibility, control, and collaboration with Shelf IQ.